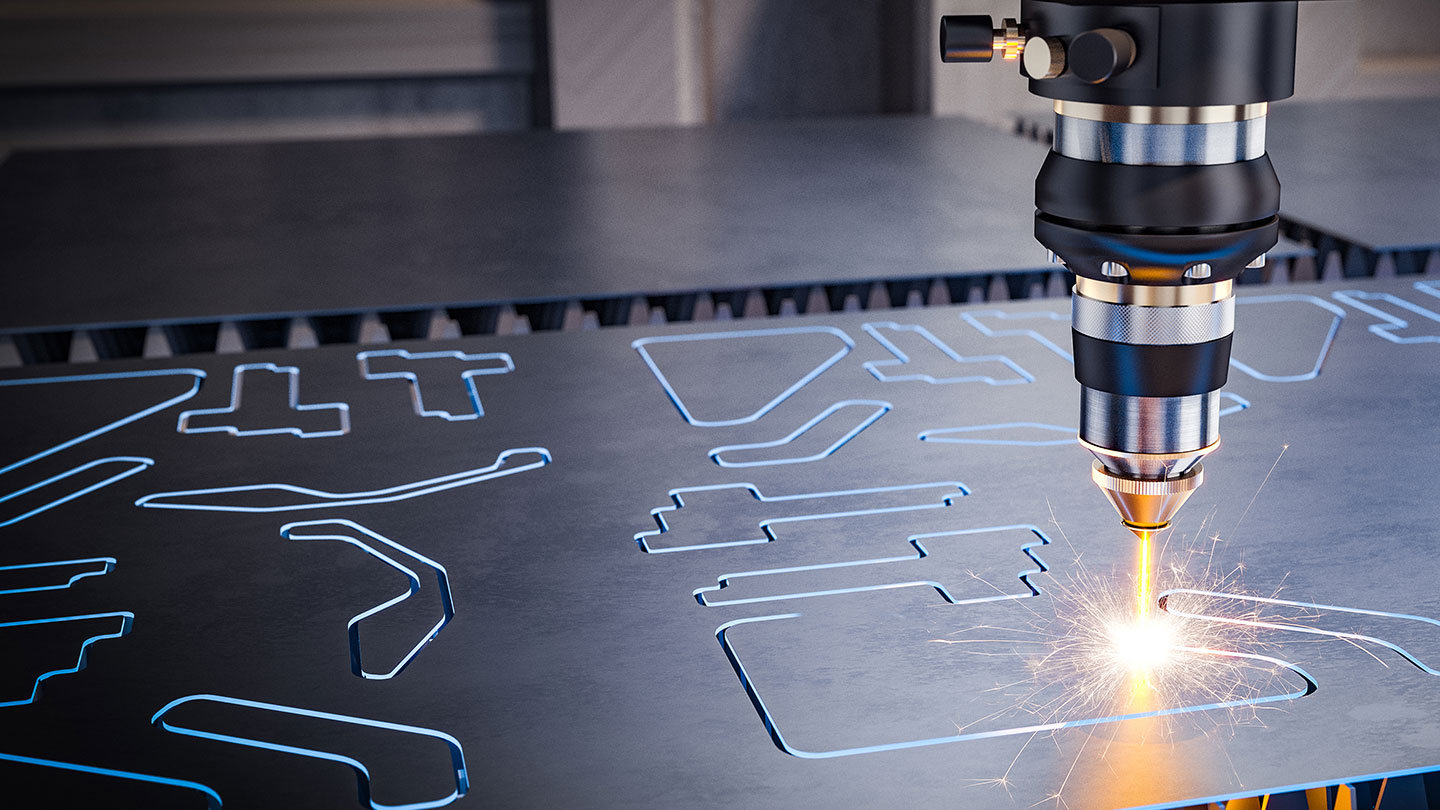

Buying a new laser

If you are considering the purchase of a laser machine, or have recently purchased, then there is a lot to think about. Our team of laser experts can hold your hand through the process and advise on a gas supply solution that will meet your current requirement as well as your future business ambitions.

It’s important to consider your gas supply mode and supplier as early as possible in the process. The correct choice of gas supply will have an impact on your overall laser running operation costs, your cut quality and your machine installation.

Gas Solutions - you will need assist gas

ASSIST GAS (or cutting gas) is a jet of gas that effectively blows away the molten material to create the cut. A clean cut requires high purity gas. The gas will often need to be delivered at a high pressure and at a set flow rate. These parameters will be determined by your specific laser model.

NITROGEN is used for most cutting applications – in particular stainless steel and aluminium. The material is heated to melting temperature by the laser beam and the nitrogen gas blows out the melt to create the cut and cools to prevent oxidisation. We have market-leading nitrogen supply modes to maximise productivity: the largest capacity cylinder packs in the industry and our high pressure liquid supply which eliminates all downtime when refilling.

OXYGEN is used for cutting unalloyed or low alloyed mild/carbon steels whereby the material is heated to ignition temperature by the laser beam and burned in an oxygen jet. Pressure, the shape of the cutting jet and gas purity determine cut quality and cutting speed. We offer oxygen in various purities and a full range of supply modes to tailor the supply to your specific requirements.

Calculating Assist Gas Consumption

A common question asked is “how much gas will I require?“. This answer is a function of nozzle size, material, material thickness, machine speed, flow rate and uptime.

Your laser manufacturer can provide the necessary data points. However, if you would like a more detailed calculation please contact us and ask for a free laser gas consumption consultation.

What about Resonator Gas?

Lasing gas (or resonator gas) is a precise gas mix required to generate the laser beam. Only CO2 laser machines require resonator gas and not fibre lasers.

Depending on your laser manufacturer’s specifications you will either need individual cylinders of pure gas or a pre-mixed gas cylinder. The volume of gas required is very small – possibly only 2 or 3 cylinders per year (depending on laser uptime) however, the gases need to be ultra pure to ensure the highest quality beam characteristics are consistently achieved.

All our resonator gases meet or exceed the gas purity and mix accuracy specifications of the world’s leading laser manufacturers.