If you are buying a laser for the first time, the information and considerations can be overwhelming. For this reason, we often experience that the choice of gas supplier is left to the very end of the procurement process. However, if you are new to laser cutting or buying an additional machine, it is crucial to consider your gas supply mode and gas supplier early in the process. The correct choice of gas supply will have an impact on your overall laser running operation costs and cut quality.

The same can be said of existing laser users – your productivity, quality and overall return can be greatly improved by partnering with a gas supplier with experience in the laser market.

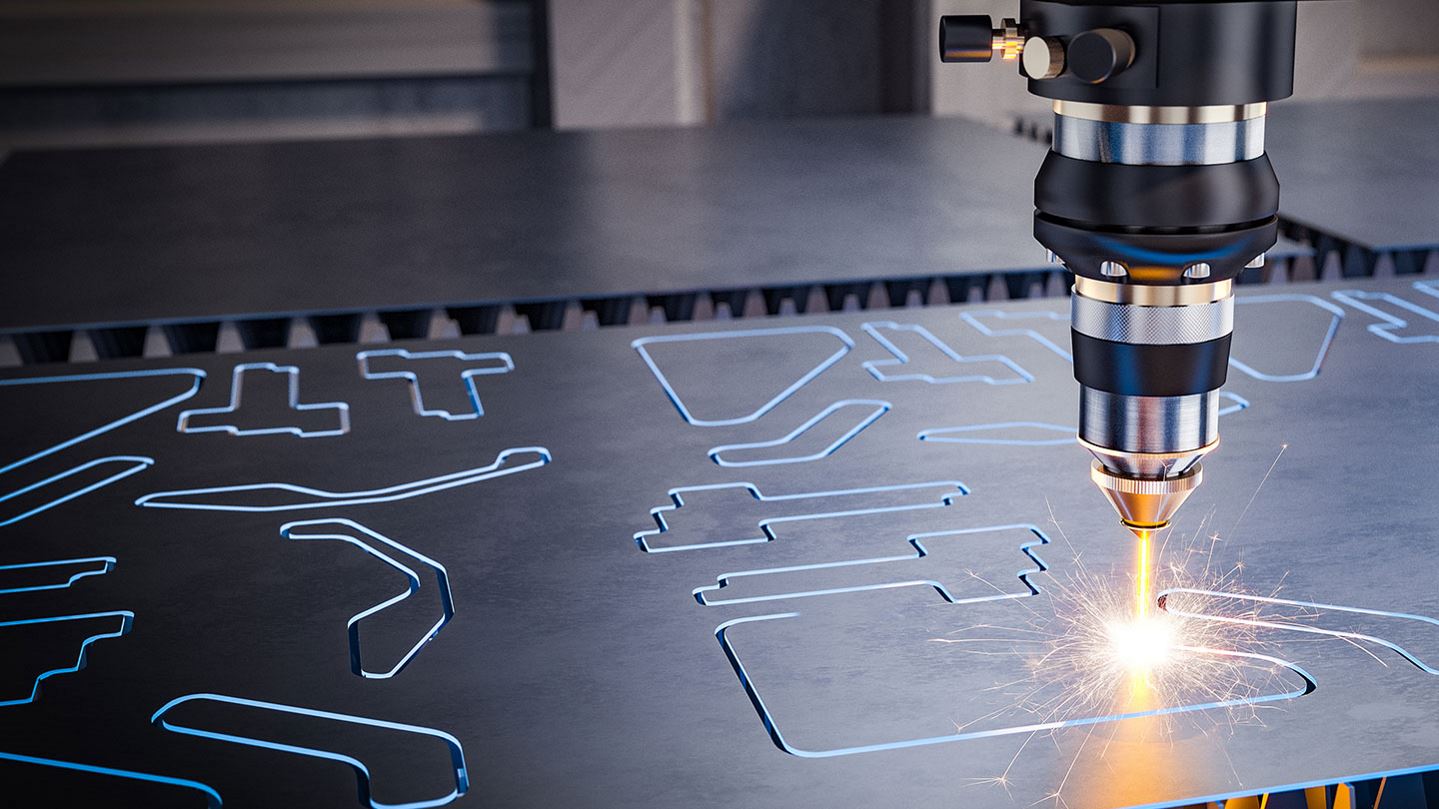

Assist gas (or cutting gas) is a jet of pressurised gas that effectively blows away the molten material to create the cut. A clean cut requires high purity gas. The gas will need to be delivered at a set flow rate and often at high pressure. These parameters will be determined by your specific laser model.

Oxygen or Nitrogen Assist Gas?

Assist gas is a fundamental requirement of laser cutting and a key variable in cut quality. The choice of assist gas depends on the material being cut and material thickness.

Nitrogen is used for most cutting applications, in particular stainless steel and aluminium. The material is heated to its melting temperature by the laser beam and the nitrogen gas blows out the melt to create the cut. Nitrogen creates a clean unoxidised cut.

Traditionally carbon steel (including mild steel) was always cut with oxygen, whereby the material is heated to ignition temperature by the laser beam and burned in an oxygen jet. We offer oxygen in various purities and a full range of supply modes to tailor the supply to your specific requirements.

With the latest more powerful machines, thinner carbon steel (<10mm) is often cut with nitrogen, making this the most commonly used assist gas in the market. Air Products has leading nitrogen supply modes to maximise productivity: the largest volume cylinder packs on the market and our high-pressure liquid supply which eliminates all downtime when refilling.

Gas Supply Mode?

Whereas gas purity is the key determinant of cut quality, gas supply mode has a significant impact on the productivity and efficiency of your laser. You need to ensure sufficient gas is available when your laser machine is running and eliminate operational costs associated with gas handling.

Laser gas can be supplied in individual cylinders, cylinder packs or cryogenic liquid supply. Liquid is the ideal solution for any laser operation using more than 10 cylinders or 1 cylinder pack per month. The benefit of a liquid solution is continuous gas supply which reduces the risk of the laser shutting down mid operation due to a lack of gas and resulting in either material write-off or laser damage. Liquid supply is also safer and more efficient, as it involves no handling of gas cylinders plus Air Products’ tanks are monitored remotely, so the risk of running out of gas is much lower.

For medium-sized operations we recommend our unique compact on-site high-pressure CryoEase® service. This service, unlike competitor liquid offerings, allows your gas to be refilled while your laser is still running, meaning no loss in vented gas or production time – even at high pressure.

For larger operations bulk tanks are recommended which are available in various pressures and flow rates to suit all business requirements.

Modern tanks are designed to be durable and maximise the amount of gas in the smallest footprint. Our highly competitive rental package includes maintenance and services making it a hassle-free install-and-go option.

If your operation is large enough to benefit from a liquid supply, we recommend you start working with cylinder packs which will enable us to size and specify your tank accurately. This then ensures a seamless transition to liquid.

The level of engineering required will depend on the specific liquid solution chosen, however, we will work around you to ensure minimal business interruption during the installation. We can provide additional engineering services for pipework and equipment installation or you may choose to manage this yourself.

Determining the optimal supply mode and size involves many factors such as flow rate, bar pressure and laser uptime. Each business set-up is different so contact us to discuss your objectives and requirements, we will work with you to find the most suitable gas supply solution.