Ask the Expert

“Why should I consider switching to CryoEase® service”

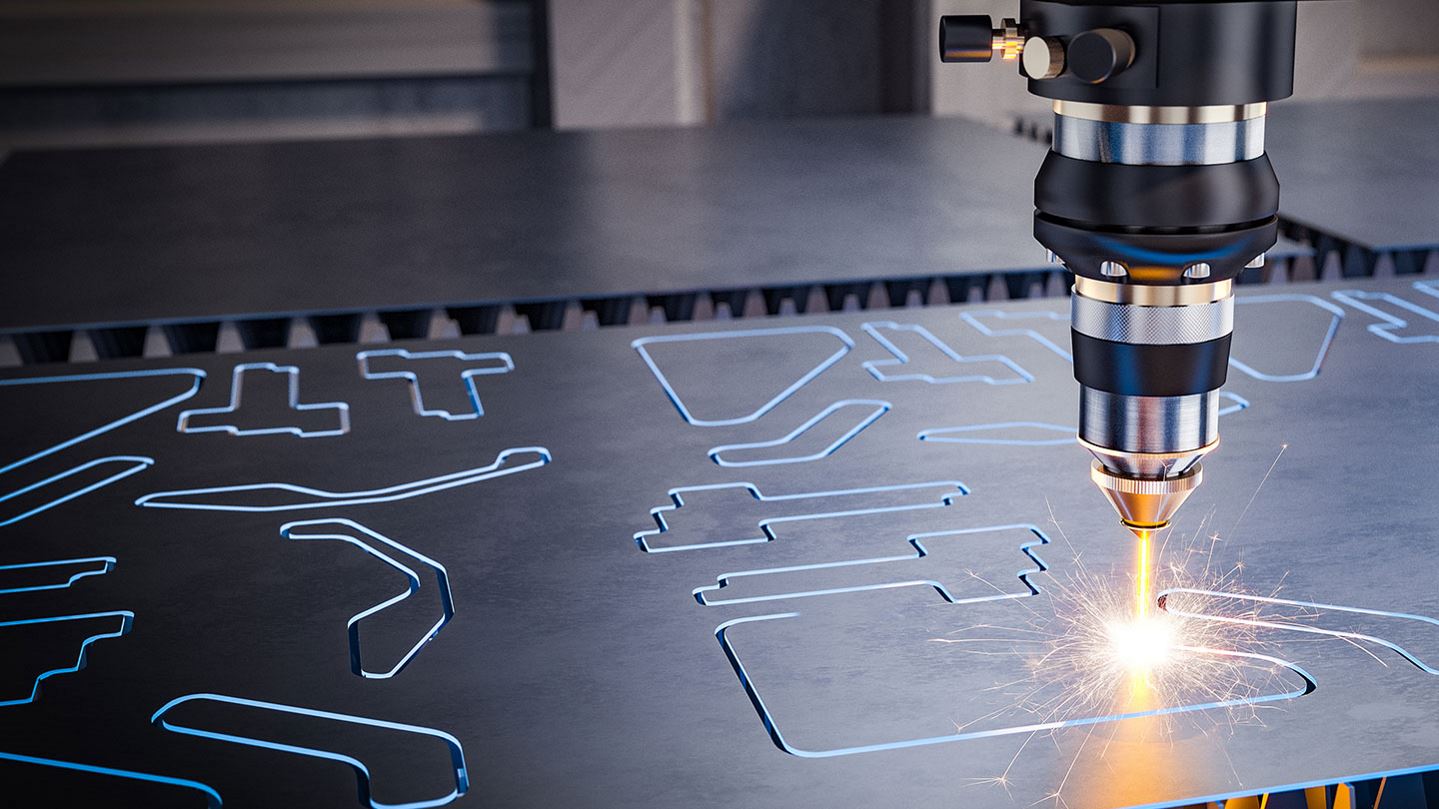

The high pressure CryoEase® tank and delivery service combination means that you never need to shut down production to refill your gas tank; meaning maximum ouput. It also means that you never run out of gas, as we monitor your usage and schedule refilling automatically.