Process gases designed for welding stainless steels

WE HAVE GAS SOLUTIONS FOR YOUR BUSINESS – SELECT BELOW

Process gases for high-quality welding of aluminium and its alloys

MIG/MAG welding gases designed to deliver optimum performance

TIG welding gases designed to improve weld quality and to reduce rejects

Lasers, oxy-fuel and plasma applications

Investing in robotic welding equipment is a significant financial commitment. Ensure you maximise your welding output capacity

Going the extra mile to ensure significant gas savings and improved weld quality

Welding Equipment

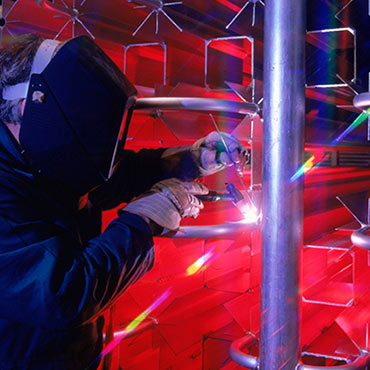

Benefits of Maxx® Gases

Maxx® gases have a positive impact on various aspects of the welding operation leading to an overall lower cost per metre welded:

- Lower reject rates – greater weld penetration, minimal defects

- Visual improvements – smoother, cleaner, brighter welds

- Higher productivity – up to 35% increase in manual weld travel speeds and less post-weld cleaning

- Lower wire consumption – flatter welds and minimal spatter generation

- Reduced power consumption

Mode of Supply

Integra® Cylinder

Air Products' Integra® cylinder was developed to meet the growing production and safety demands of today's welding industry.

CryoEase® Microbulk Solutions

A convenient and cost-effective solution for larger operations. CryoEase® tanks are available in a range of sizes. The CryoEase® service simplifies your gas supply by eliminating the need to handle cylinders, stock taking and ordering.

Welder's Handbook

Request a download of our industry-leading comprehensive guide to gas shielded arc welding and oxy-fuel cutting.

Contact Us

We offer FREE on-site welding gas demonstrations by our qualified Welding Specialists with no obligation to buy. Complete the form or call us on 0800 389 0202

Don't let spatter grind you down

What is the best gas for TIG welding austenitic stainless steel?