How Can Air Products Help Your Cryoroom Project?

Managing a cryoroom project is a very complex process with many factors to take into consideration which include:

- Cryoroom location and layout

- Current and future requirements

- The right equipment

- Siting of the freezers

- Storage options

- The right materials for the room

- Pipework considerations

- Filling options

- Extraction systems

- Oxygen level monitoring

- Health and safety

- Security of access

- The right partners

As a market leader in this sector, Air Products can guide you through this process and provide expert advice on the best solution for your needs.

Ask the Expert

Stephen Robinson

Product Manager - Life Science

“There are so many things to consider for our new cryoroom. How can I ensure I get them all right?”

Getting the right balance of location, equipment and gas supply can seem daunting. Air Products can carry out a site visit to advise on all the options.

Liquid Nitrogen

Nitrogen is valued both as a gas for its inert properties and a liquid for cooling and freezing. Our experienced applications team can use their knowledge of your industry and application to provide you with a supply and technology solution to meet your unique needs.

Download Liquid Nitrogen Safetygram 7 brochure

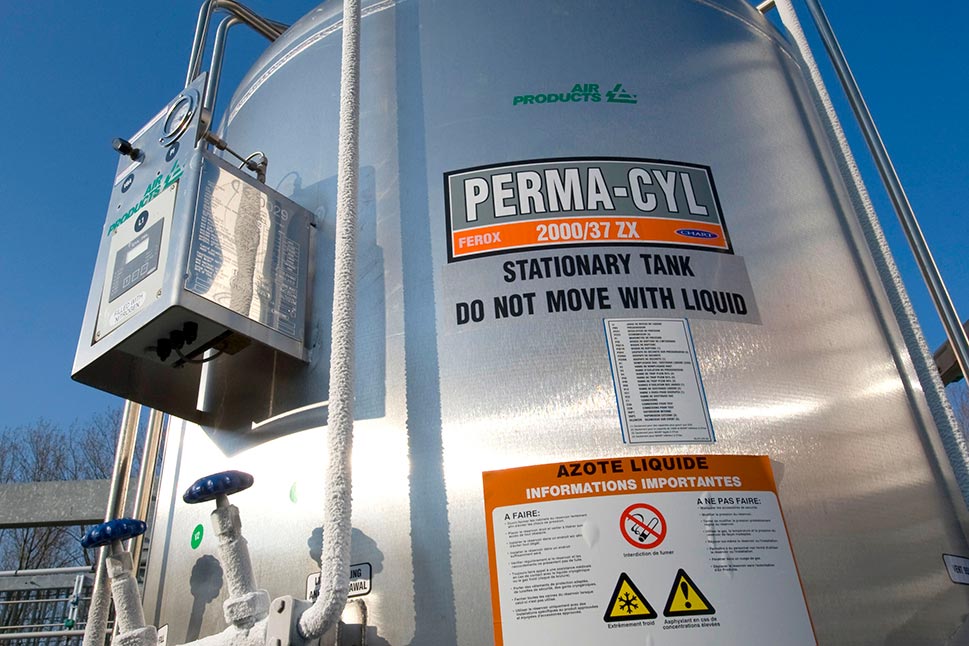

CryoEase® Microbulk Solutions

CryoEase® microbulk technology is a modern concept where your gas is supplied by filling on-site vs. the traditional method for smaller volume usage, where gas is supplied by swapping full for empty cylinders and dewars. CryoEase® microbulk supply features specially designed trucks with integrated controls and flexible storage tank options. End usage can be provided as pure gases, cryogenic liquids or gaseous mixtures via a blender installed at your site.

LEARN MORE