Get in touch with one of our technical experts.

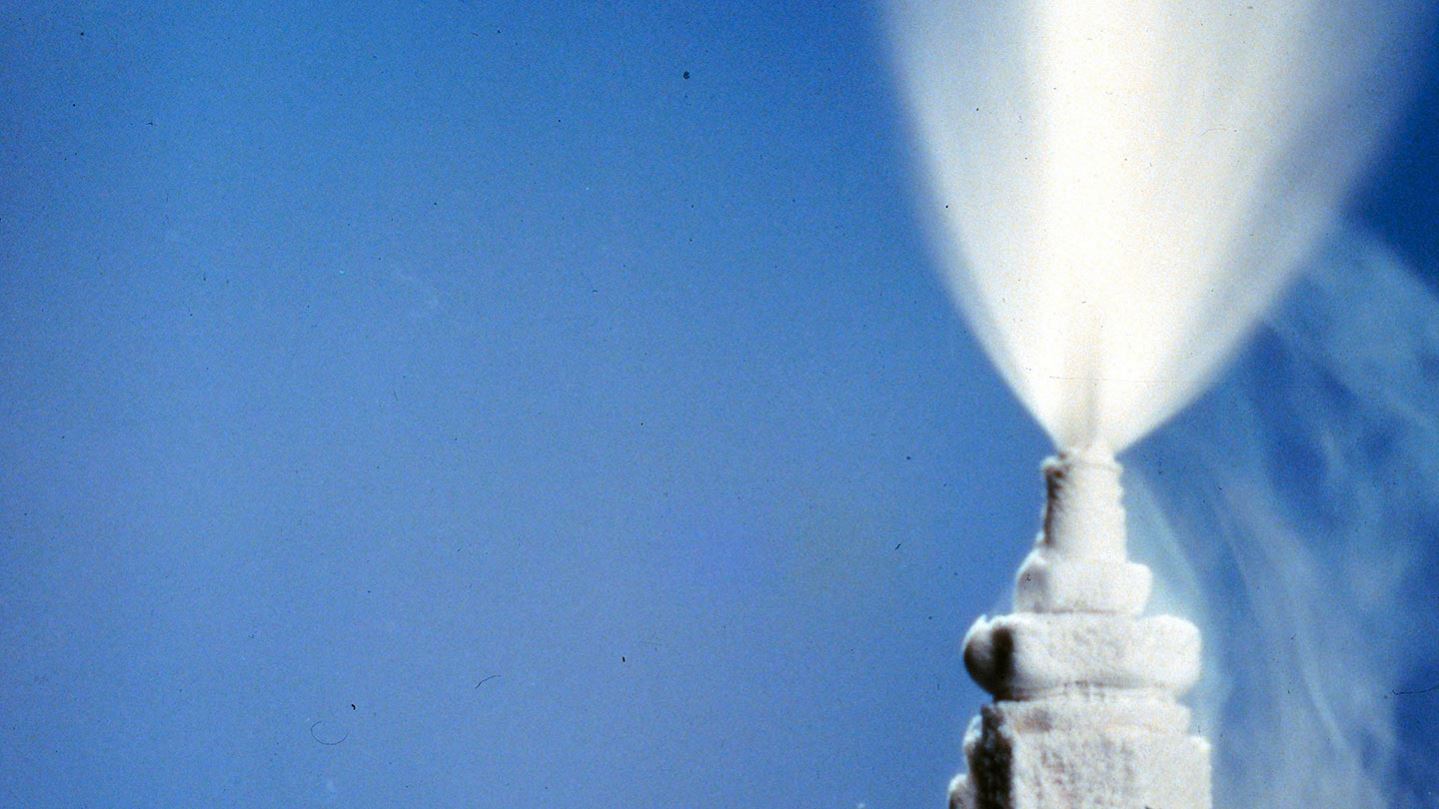

Put Air Products' cryo-tempering and cryogen supply expertise to work for you.

Ask the Expert

Liang He

Advanced Materials Processing R&D Engineer, North America

“Why would I want to cryogenically treat tool steels? Does it really affect the microstructure?”

After austenitizing and quenching, tool steels are sometimes subjected to cold treatment at approximately –80°C (-112°F), followed by tempering. Primarily, the cold treatment is done to increase strength, improve dimensional or microstructure stability, and improve wear resistance. These benefits are due to the transformation of retained austenite to martensite. Some studies show that lowering the cold treatment temperature below –100°C (–148°F) does not significantly increase the amount of retained austenite-to-martensite transformation—therefore it does not result in additional benefits. However, other studies show that compared to cold treatment (–80°C/-112°F), cryogenic treatment (–190°C/-310°F) further improves wear resistance.

Cryogenic Quenching of Steel Revisited

Cryogenic treatments of alloy steels have been claimed to significantly increase wear resistance and toughness through the interplay of three effects: completing martensitic transformation, promoting uniform precipitation of fine carbides and imparting residual stresses.